Global Hotline

Global Hotline

Introduction: Why Standard LCD Displays Are Becoming Less Suitable

In fields such as industrial control, medical devices, new energy, and smart terminals, LCD displays are no longer simple information output components. They have become a critical part of device functionality, reliability, and user interaction.

However, standard LCD displays are highly fixed in terms of size, brightness, interfaces, and environmental adaptability. As device functions continue to evolve, these limitations make it increasingly difficult for standard displays to meet real application requirements. As a result, more manufacturers are realizing that standard displays are restricting overall product design and long-term stability.

What Is a Custom LCD Module (Custom LCD Module)?

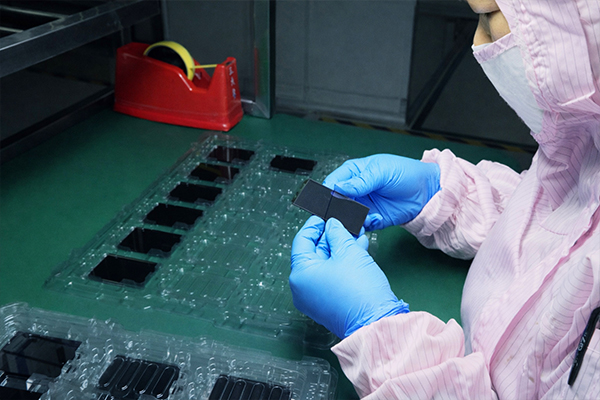

A custom LCD module refers to a display solution that is systematically designed based on the specific application requirements of a device.

Unlike standard LCD displays, custom LCD modules allow flexible definition of screen size, resolution, brightness, viewing angle, interface type, and backlight structure. Depending on the application, touch panels and cover glass can also be integrated into the design.

In short, the goal of a custom LCD display is not universality, but precise compatibility with the device itself.

What Practical Problems Can Custom LCD Modules Solve?

Custom LCD modules are mainly used to address the following common issues:

1. Structural Mismatch

Standard displays come in fixed sizes, often forcing repeated adjustments to the enclosure or internal structure. Custom solutions are designed to match the device structure directly, reducing design compromises.

2. Inadequate Display Performance

In environments with strong ambient light, low temperatures, or long operating hours, standard LCD displays often struggle to maintain stable performance. Custom LCD modules can optimize brightness and display parameters according to actual operating conditions.

3. Long-Term Reliability Concerns

Before mass production, custom LCD modules typically undergo backlight testing, parameter verification, and stability testing. This helps reduce failure rates, minimize after-sales issues, and improve overall product reliability.

When Should You Choose a Custom LCD Display?

A custom LCD module is usually the better choice in the following situations:

1.The device structure is fixed and standard displays do not fit

2.There are clear requirements for brightness, stability, or consistency

3.The product requires long-term supply and stable mass production

4.The display is a critical functional component of the device

Conclusion: Custom LCD Modules Are a Long-Term Solution

When standard LCD displays can no longer meet device requirements, custom LCD modules are not a complex or expensive alternative, but a more stable and controllable long-term solution.

By introducing custom display solutions at the design stage, manufacturers can achieve a better balance between performance, reliability, and total cost.

About KANOU Display

KANOU Display specializes in the design and manufacturing of custom LCD modules and custom LCD displays. Serving industries such as industrial control, medical devices, new energy, and smart terminals, KANOU Display provides complete display solutions from concept design to mass production, helping customers reduce development risks and achieve long-term product stability.